Sheet Metal Fabrication

Witcool provides premium sheet metal fabrication services, combining innovative technology and professional craftsmanship to produce high-quality, precise, and long-lasting metal components. Our knowledge covers multiple industries, delivering unique solutions tailored to your individual requirements. Witcool’s advanced facilities and professional team ensure outstanding results from basic concept to final production. Witcool provides dependable, cost-effective sheet metal fabrication that satisfies the highest industry standards.

- Precision Bending & Forming

- Advanced Fabrication Techniques

- OEM/ODM Service Available

- 7/24 Engineering Support

Start A New CNC Quote

STEP | STP | SLDPRT | STL | DXF | CAD | PDF files

- All uploads are secure and confidential.

We always focus on quality and are ISO 9001 certified.

Professional Team

Our professional team delivers exceptional expertise and dedication to meet all your project needs.

Top Quality

Witcool provides top-quality sheet metal fabrication with precision, durability, and exceptional craftsmanship for various industries.

Fast Delivery

Enjoy fast delivery with Witcool, ensuring your orders arrive quickly and efficiently every time.

What Is Sheet Metal Fabrication?

Building metal structures and components by cutting, bending, and assembling flat metal sheets is known as sheet metal fabrication. Usually developed with computer-aided design (CAD) software, it begins with a design meant for guaranteed accuracy. Usually composed of steel, aluminium, or brass, the metal sheets are then sheared, laser-cut, or plasma cut to size. Once cut, press brakes or other equipment shapes the metal.

Following shaping, the pieces are welded, riveted, fastened, or adhesively put together to form the finished good. In many different sectors, including automotive, aerospace, electronics, and construction, this method is vital for producing everything from vehicle bodies and aeroplane wings to enclosures for electronic equipment and structural components for buildings.

To create durable, high-quality parts that satisfy exact requirements and industry standards, sheet metal fabrication calls both innovative machinery and expert workmanship.

Overview of Sheet Metal Farbrication

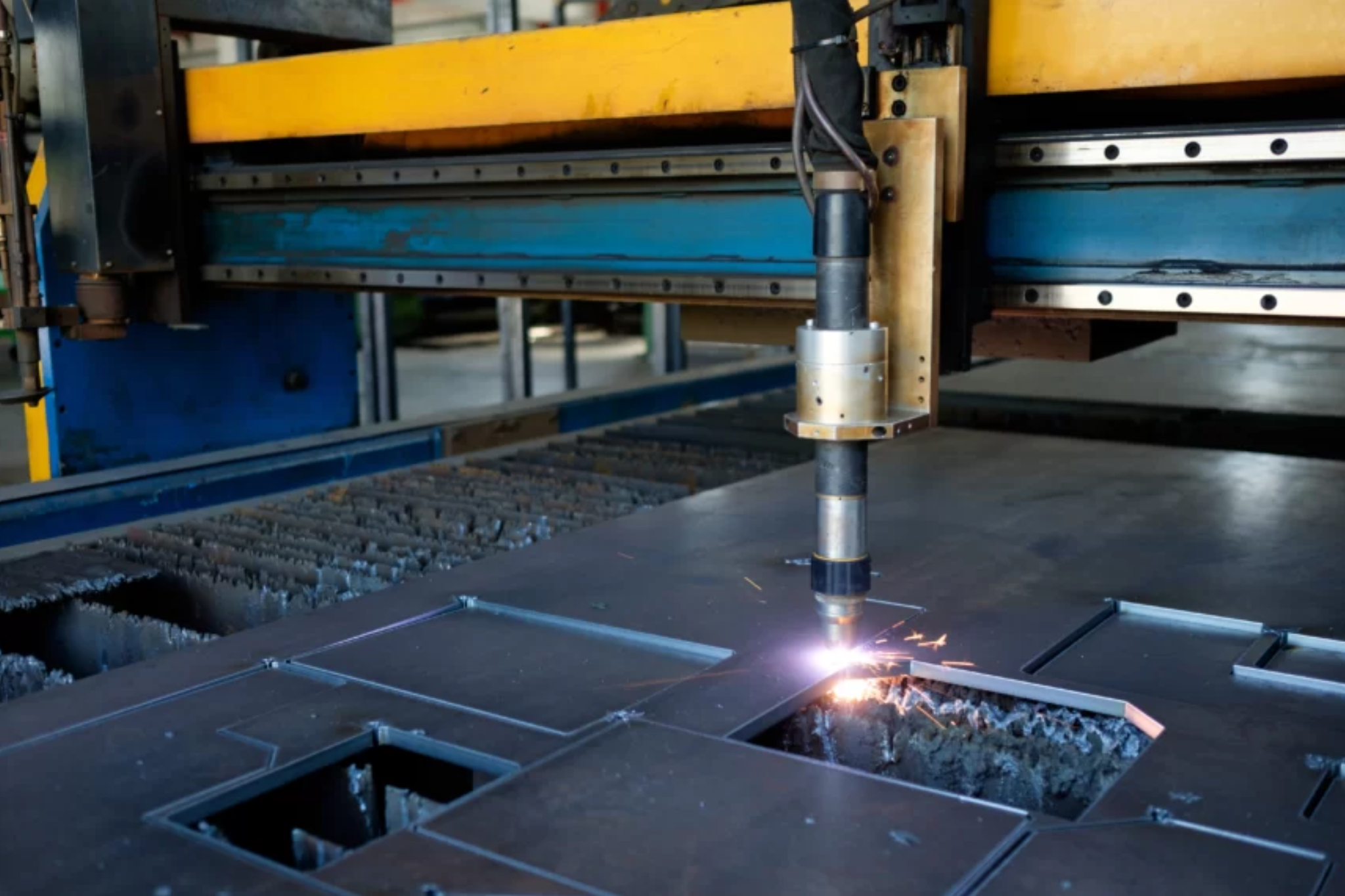

Cutting

Cutting methods in sheet metal fabrication include laser cutting, plasma cutting, and waterjet cutting.

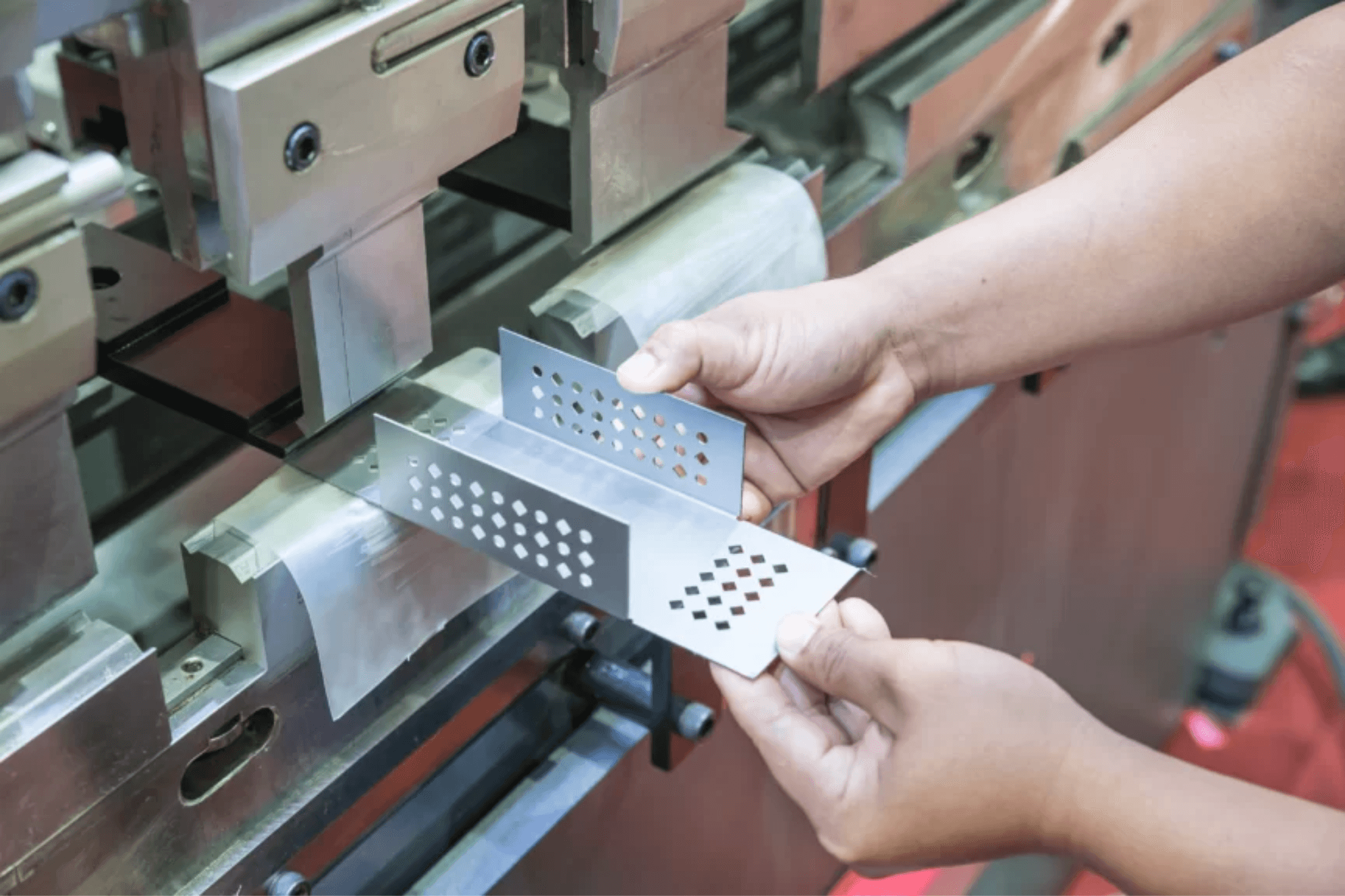

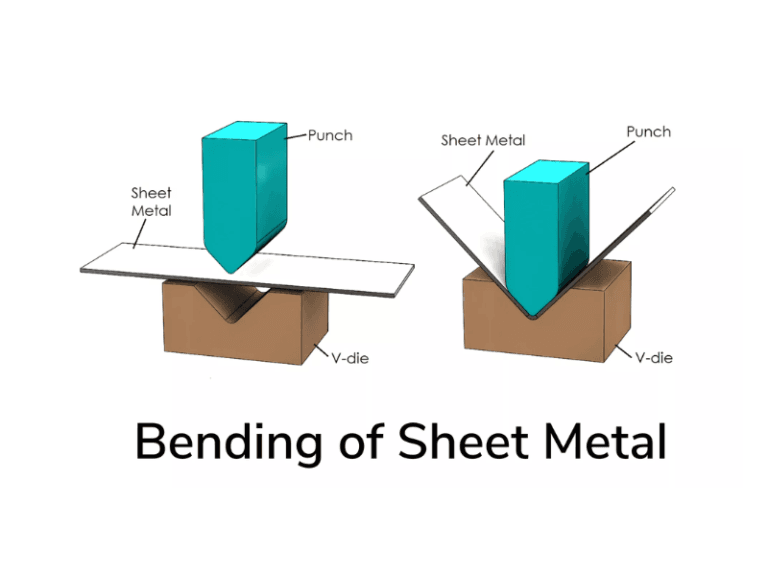

Bending

Bending in sheet metal fabrication involves shaping metal sheets using press brakes or rollers to achieve desired angles and forms.

Forming

Forming involves bending, shaping, and molding metal sheets to achieve desired structural shapes and components.

Welding

Welding joins metal pieces together by melting them, creating strong connections crucial for structural integrity in sheet metal fabrication.

Sheet Metal Farbrication Capabilities

Witcool specializes in sheet metal fabrication, providing precise cutting, bending, welding, and assembly services for various industries’ needs.

Cutting

Three main cutting techniques are crucial for accuracy and efficiency in sheet metal manufacturing.

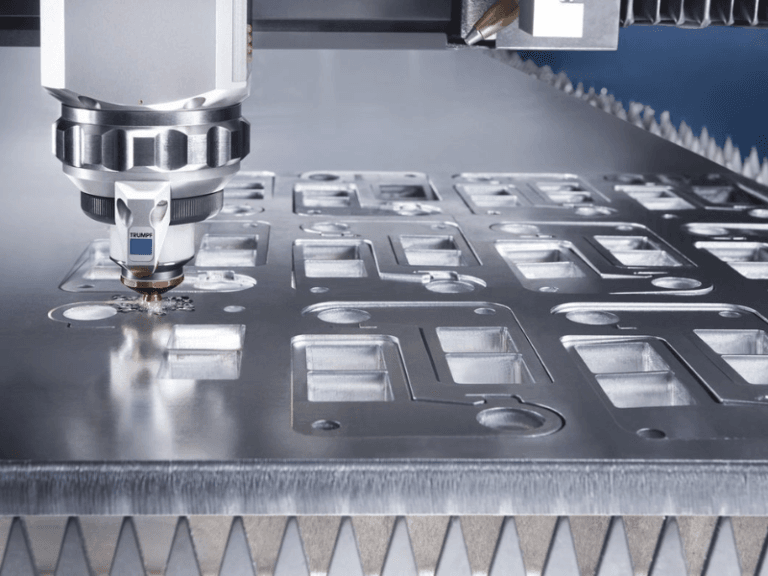

Laser cutting

Laser cutting is a precise method that uses a concentrated laser beam to cut sheet metal cleanly and accurately, creating sharp edges by melting, burning, or vaporizing the material. This efficient technique minimizes waste and finds applications across multiple industries.

Plasma Cutting

Plasma cutting breaks through electrically conducting materials using a stream of heated plasma. To produce the plasma, an electric arc is sent across a gas, say nitrogen or oxygen. Common in industrial uses, it works well for cutting heavier metal sheets.

Waterjet cutting

To cut sheet metal, waterjet cutting employs a high-pressure spray of water—sometimes combined with abrasive particles. This approach is very exact and generates little heat, therefore avoiding material bending or distortion. Among the materials waterjet cutting can handle are metals, composites, glass, and stone.

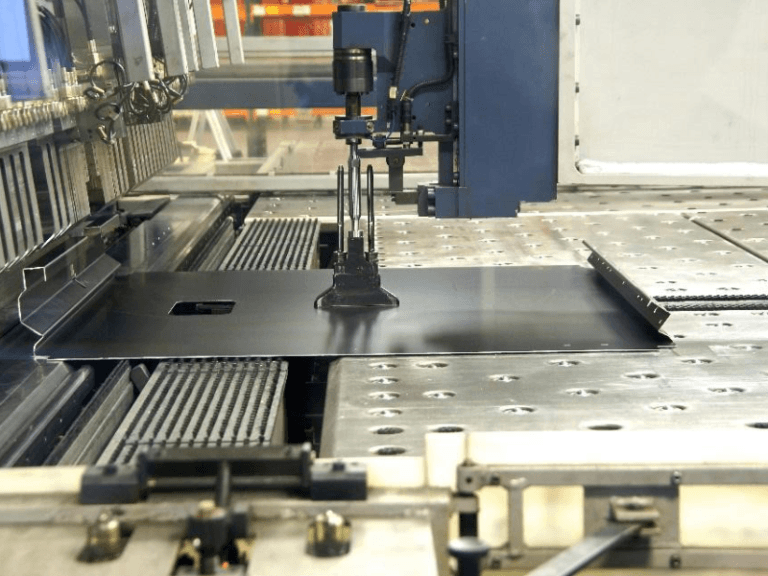

Bending

Bending is a critical step in sheet metal manufacturing. It applies force to mould metal sheets into the necessary shapes. Metal is bent at particular angles using tools such as press brakes, which are made up of a punch and die. This method produces a wide range of forms, from basic bends to sophisticated, multi-angle arrangements.

Bending provides the advantage of making strong, durable pieces all while preserving the material’s integrity. This makes it perfect for applications such as automotive, aerospace, and construction. Modern press brakes are extremely precise, enabling tight tolerances and reproducibility across several pieces. Bending is critical for transforming sheet metal into usable, high-quality components.

Forming

Forming in sheet metal manufacturing involves shaping metal sheets into complex forms without adding or removing material. Techniques like bending, stretching, and deep drawing efficiently create intricate shapes for mass production.

Hydroforming uses high-pressure hydraulic fluid to mold metal into a die, producing lightweight yet robust components, making it popular in the automotive and aerospace industries.

These forming techniques are crucial for their precision and consistency, allowing for the production of a diverse range of products, from everyday items to specialized industrial components, with enhanced strength and durability.

Welding

In metal fabrication, welding is essential for joining metal pieces by melting their edges and adding filler material to create strong bonds.

MIG (Metal Inert Gas) welding, known for its speed and ease, produces strong welds for thicker metals, making it popular in construction and automotive industries, while TIG (Tungsten Inert Gas) welding offers precise control for thinner materials and complex projects, widely used in aerospace and for non-ferrous metals like aluminum and magnesium.

Welding is crucial in manufacturing, construction, and automotive sectors, ensuring structural integrity and durability through skilled welders.

Sheet Metal Materials

Steel

Stainless Steel

Aluminum

Copper

Bronze

1018

SUS 304

A6061

C1100

CuSn4

S45C

SUS 303

A5183

CuZn15

LPB1

SKD11

SUS 316L

A6082

2.0335

LPB1-C

A36

SUS 410

A2017

Cu-DHP

CA104

General Tolerances for Sheet Metal Fabrication

Our sheet metal shops follow ISO 13485 tolerances to deliver consistent quality. For tolerances beyond these standards, detail your needs on the design schematics or reach out to our engineers.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Dimension Detail

Metric Units

Imperial Units

Edge to edge, single surface

± 0.127 mm

± 0.005” in.

Edge to hole, single surface

± 0.127 mm

± 0.005” in.

Hole to hole, single surface

± 0.127 mm

± 0.005” in.

Bend to edge / hole, single surface

± 0.024 mm

± 0.010” in.

Edge to feature, multiple surface

± 0.762 mm

± 0.030” in.

Over formed part, multiple surface

± 0.762 mm

± 0.030” in.

Bend angle

± 1°

± 1°

By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify them in your drawing.

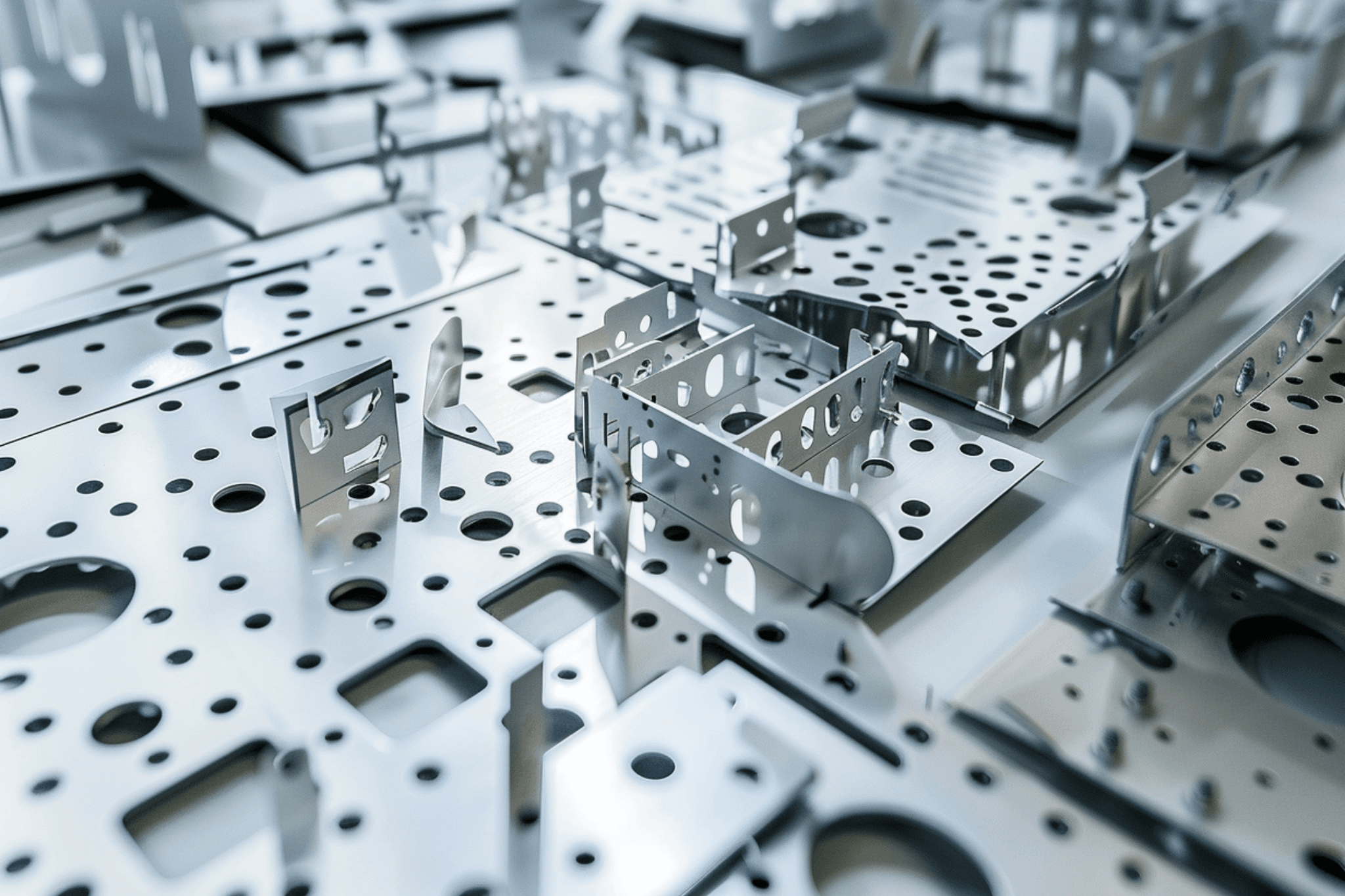

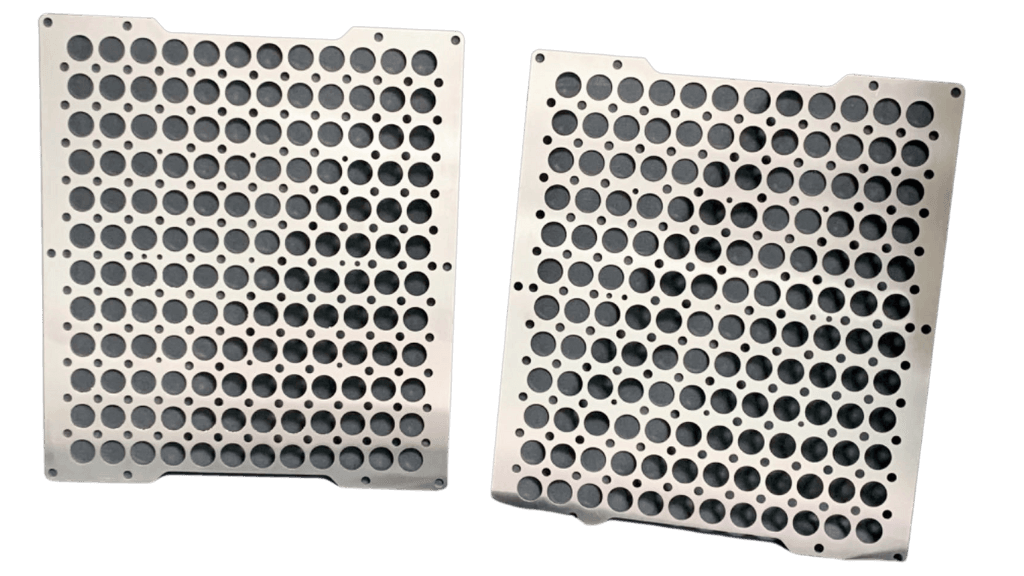

PART STUDY

Precision Stainless Steel Plates for Machining Solutions

Material: 1.4301 (SUS 304)

Surface Treatment: No burrs

Qty: 1500 Pcs

Application: The high-precision stainless plate made from SUS 304 stainless steel is an essential component used in various high-performance applications across multiple industries. Known for its excellent machinability, corrosion resistance, and durability, this stainless plate meets rigorous standards required for precision-engineered parts.

Sheet Metal Farbrication Resources

Sheet Metal Fabrication

Witcool Machining offers comprehensive sheet metal fabrication services, specializing in custom and precision CNC fabrication.

Whether it’s for automotive, aerospace, or industrial applications, our expert team delivers high-quality and durable metal components tailored to your specifications.

With advanced equipment and a commitment to excellence, we ensure that every project meets the stringent standards of quality and precision. Discover how our sheet metal fabrication services can enhance your manufacturing process and help you achieve your production goals.