Design and Engineering

In design and engineering, we prioritize producing bespoke solutions that properly fit our clients’ requirements, this includes presenting bespoke alternatives backed up by strong technical competence and diligent after-sales service. Our mission is to guarantee that our clamping fixtures not only meet, but surpass, expectations by offering dependable performance and long-term satisfaction in a wide range of industry applications.

Developing the Customer Relationship

About Us

Introduction

We are proud to offer comprehensive design and engineering services, backed by a team of experienced professionals.

- ISO 9001:2015 Certified

- Tolerances as Tight as ±0.005mm

- No MOQ: From 1 to 5000+ Pieces

- Lead Time as Fast as 1 Day

Our Capabilities

Design Expertise

Our design team excels in creating innovative solutions tailored to your needs. We transform concepts into detailed designs, ensuring functionality and aesthetic appeal.

Engineering Excellence

Our engineering team has a wealth of experience and adheres to the highest industry standards. We utilize the latest technologies to deliver precise and reliable engineering solutions.

OEM/ODM Service

We specialize in OEM/ODM projects, providing customized designs and manufacturing solutions. Our process ensures that your specifications are met with the utmost accuracy.

Process Overview

PART STUDY

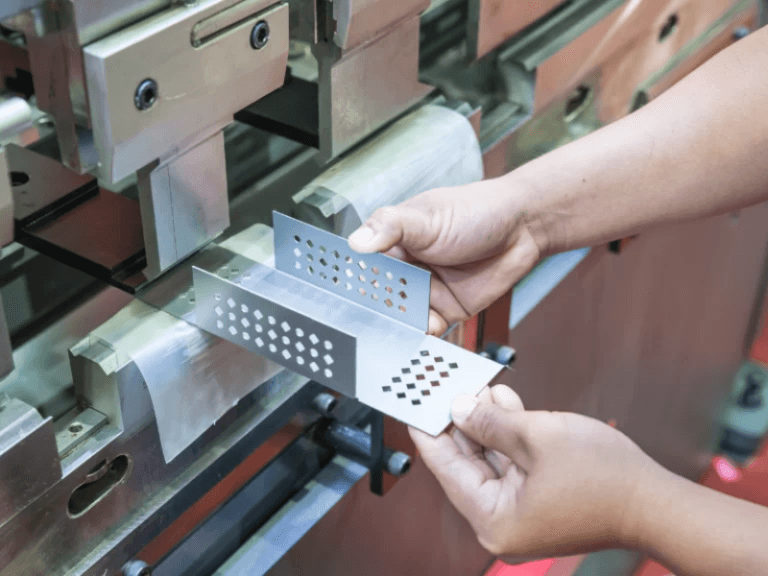

3D Printing Clamp

Material: White ABS

Surface Treatment: NONE

Qty: 1Pc

Application: This 3D printed clamp is used in the medical industry for assembling diagnostic devices.

Its robust construction and precise dimensions ensure reliable performance in critical medical applications, making it ideal for holding components securely during the assembly process.

The use of white ABS provides excellent strength and durability, essential for maintaining high standards in medical device manufacturing.

Learn more about 3D printed clamps in the medical industry.

Why Choose Us

Witcool maximizes your ROI by delivering fast, cost-effective services that uphold your stringent standards.

Exceptional Quality Control

Our rigorous quality control ensures that every CNC machined product meets the highest requirements. This devotion to quality produces consistently outstanding products, ensuring that our consumers receive only the finest.

Certifications to Meet Your Need

Witcool is ISO 9001:2015 certified

Material Quality Assurance

Witcool sources materials from long-term, trusted manufacturers. Each batch of workpieces undergoes rigorous analysis before machining.

Design Requirements Verification

Our engineers will verify your requirements and choose the most suitable processing method.

First Article Inspection

We will inspect the first articles twice during volume production to ensure we produce the correct parts from the start.

Final Quality Inspection

Witcool conducts final inspections on every finished part, measuring sizes, tolerances, and features to ensure they meet your specifications.

Inspection Reports Available on Request

We provide samples with complimentary inspection reports for medium and high-volume orders, and additional reports upon request.

Cost-Effective Solutions

We prioritize both quality and affordability as a custom CNC machining manufacturer. Through efficient processes and economies of scale, we deliver precise, high-quality products at competitive prices, ensuring exceptional value for our clients.

Material Optimization

Our advanced nesting software allows us to maximize material usage, resulting in a typical material cost reduction of “15-20%”.

Reduced Lead Times

We pride ourselves on our efficiency, offering an average lead time of “2 days”, shorter lead times mean you can bring your products to market faster, enhancing your sales potential by as much as”15%”.

Lower Rework Rates

Quality is a top priority for us. Our robust quality control processes have reduced our rework rate by “30%”. Reducing reworks not only cuts costs associated with wasted materials but also saves valuable time.

Bulk Production Discounts

We offer substantial discounts for bulk orders, which means that if you typically order in bulk, you may save 20-30%.

Experienced Team

As a custom CNC machining manufacturer, our skilled engineers, technicians, and operators bring in-depth knowledge of CNC processes, allowing us to tackle complex projects with confidence and proficiency.

Professional Skills and Certifications

Our engineering and technical staff hold various industry-recognized certifications, including CNC programming certifications and technician qualifications. On average, each engineer has over 12 years of industry experience.

Experience and Project Achievements

Our team has successfully completed various complex projects, showcasing our ability to handle intricate machining tasks. For instance, we executed a challenging project for Apple that involved producing high-precision components, meeting all specifications and delivering the project 20% ahead of schedule.

Production Efficiency and Quality Control

Through the optimization of our CNC machining processes, our engineering team has managed to improve production efficiency by 30%. This improvement has led to a substantial enhancement in our throughput while maintaining strict quality standards.

Innovation and Technological Development

Our dedication to innovation is evident in our substantial investment in research and development. Each year, we allocate 15% of our total budget to R&D initiatives.

Customer Satisfaction and Feedback

Recent surveys show that our customer satisfaction rate is over 98%, reflecting the high quality of service and products we provide.

Flexibility & Adaptability

As a leading provider of custom CNC machining services, we are committed to exceeding client expectations. Our ability to swiftly adapt to evolving requirements and urgent requests while upholding rapid lead times and precise tolerances underscores our dedication to delivering exceptional results.

Certifications to Meet Your Need

Witcool CNC Machining’s agile scheduling enables rapid responses to urgent client orders, often initiating production within 24 hours.

Customization Capabilities

With approximately 70% of its orders being custom projects, Witcool CNC Machining excels in providing tailored manufacturing solutions

Modular Equipment and Processes

Witcool employs modular design in both equipment and production processes, allowing for quick adjustments to the manufacturing line based on project requirements.

Real-Time Monitoring and Feedback System

We use a real-time monitoring system for rapid issue resolution, averaging 15-minute response times and boosting efficiency by 15%.

Close Communication with Clients

We maintain regular client communication with a 24-hour feedback cycle, allowing for swift adjustments to production schedules.